Quality Steel Since 1939

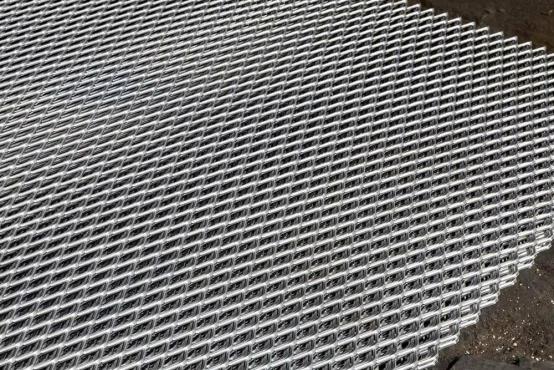

Prime Steel Expanded Metal

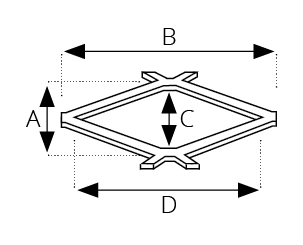

Expanded metal is a single sheet of metal that has been stretched by an expanding machine to produce a thinner metal with perforations or openings. These openings or cuts come in a wide variety of shapes and sizes, including:

- diamond (most common)

- circles

- ovals

- squares

- and hexagons

At Texas Iron & Metal, we have an extensive inventory of expanded metal in a wide variety of cut sizes and shapes. The three types of prime and less-than-prime expanded metal we carry include:

- Standard Expanded Metal

- Flattened Expanded Metal

- Expanded Metal Grating

Standard Expanded Metal

Steel sheet that has been slit and then stretched to create a diamond lattice pattern. This type can come in various sizes and weights, which makes it suitable for a wide variety of applications, including BBQ grills, benches, heavy duty shelving, industrial fan safety cover, and industrial walkways.

Flattened Expanded Metal

Standard expanded metal that passes through a cold-rolling press to flatten it. This process makes the expanded metal flatter, thinner, and longer. This lightweight version is ideal for fences, walls, partitions, grilles, and ventilation.

Expanded Metal Grating

Produced by low-carbon, heavy gauge steel plates, makes expanded metal structurally stronger and heavier than standard or flattened expanded metal. Due to its enhanced strength-to-weight ratio and durability, it is commonly used for walkways, stair platforms, cages, and industrial flooring.

Applications and Industries

Due to its diverse range of desirable qualities, expanded metal is an extremely versatile material that benefits numerous applications and industries, including:

- Building & Construction

- Architecture

- Automotive

- Agriculture

- Filtration

- Security & Defense

- Architectural design

- Engineering

Benefits

Because it is formed from a single sheet of metal, expanded metal is inherently strong with a better strength-to-weight ratio than sheet metal or perforated metal. Compared to other metal processing methods, such as perforations, expanded metal offers immediate cost savings that results in minimal raw material waste. Because there are no breaks or cuts, the knuckles formed when expanding metal can withstand great pressure and loads, provide better electrical conduction, and offers anti-slip qualities. Plus, the perforations make flat carbon expanded metals perfect for ventilation and light-in applications.

Expanded Metal in stock

| image | sku | description | size | length | expanded metal type | Quantity | Add to Quote |

|---|---|---|---|---|---|---|---|

| XM11210 | 1 1/2" #10 STANDARD EXPANDED METAL | ||||||

| XMF11213 | 1 1/2" #13 FLAT EXPANDED METAL | ||||||

| XM11213 | 1 1/2" #13 STANDARD EXPANDED METAL | ||||||

| XMF11216 | 1 1/2" #16 FLAT EXPANDED METAL | ||||||

| XM11216 | 1 1/2" #16 STANDARD EXPANDED METAL | ||||||

| XMF1126 | 1 1/2" #6 FLAT EXPANDED METAL | ||||||

| XM1126 | 1 1/2" #6 STANDARD EXPANDED METAL | ||||||

| XMF1129 | 1 1/2" #9 FLAT EXPANDED METAL | ||||||

| XM1129 | 1 1/2" #9 STANDARD EXPANDED METAL | ||||||

| XMF116 | 1" #16 FLAT EXPANDED METAL | ||||||

| XM1213 | 1/2 #13 STANDARD EXPANDED METAL | ||||||

| XM1216 | 1/2 #16 STANDARD EXPANDED METAL | ||||||

| XMF1213 | 1/2" #13 FLAT EXPANDED METAL | ||||||

| XMF1216 | 1/2" #16 FLAT EXPANDED METAL | ||||||

| XMF1218 | 1/2" #18 FLAT EXPANDED METAL | ||||||

| XMF1418 | 1/4" #18 FLAT EXPANDED METAL | ||||||

| XG3 | 3# EXPANDED METAL GRATING | ||||||

| XGG3 | 3# GALVANIZED EXPANDED METAL GRATING | ||||||

| XG314 | 3.14# EXPANDED METAL GRATING | ||||||

| XMF3413 | 3/4" #13 FLAT EXPANDED METAL | ||||||

| XM3413 | 3/4" #13 STANDARD EXPANDED METAL | ||||||

| XMF3416 | 3/4" #16 FLAT EXPANDED METAL | ||||||

| XM3416 | 3/4" #16 STANDARD EXPANDED METAL | ||||||

| XMF349 | 3/4" #9 FLAT EXPANDED METAL | ||||||

| XM349 | 3/4" #9 STANDARD EXPANDED METAL | ||||||

| XG4 | 4# EXPANDED METAL GRATING | ||||||

| XGG4 | 4# GALVANIZED EXPANDED METAL GRATING | ||||||

| XG427 | 4.27# EXPANDED METAL GRATING | ||||||

| XGG427 | 4.27# GALVANIZED EXPANDED METAL GRATING | ||||||

| XG5 | 5# EXPANDED METAL GRATING | ||||||

| XG625 | 6.25# EXPANDED METAL GRATING | ||||||

| XGG625 | 6.25# GALVANIZED EXPANDED METAL GRATING | ||||||

| XG7 | 7# EXPANDED METAL GRATING |

LESS-THAN-PRIME© EXPANDED METAL FOR SALE

Texas Iron & Metal offers one of the largest supplies of surplus steel for sale in Texas, including less-than-prime expanded metal. Less-Than-Prime (LTP©) expanded metal is a viable option to prime steel when visible imperfections, minor surface defects, odd shapes, and miscuts are not an issue. In most cases, this cost-saving alternative offers all the benefits of the prime version.

Contact one of our steel experts to help you determine which type of expanded metal is best for your next Less-Than-Prime expanded steel project needs.

BUY EXPANDED METAL TODAY

While “Texas” is in our name, Texas Iron & Metal has grown from a local to regional to nationwide supplier of both prime and surplus steel and pipes. We strive to be your one-stop provider for all your steel needs by offering value-added services such as saw cutting, shearing, punching, and iron working.

We stock both prime and surplus steel and pipes in thousands of shapes, sizes, grades, and lengths in our 10-acre facility located minutes from downtown Houston. Our central location and national distribution centers throughout the US allow us to quickly ship our inventory locally, regionally, and nationally in the most cost-effective way. Whether it is a bulk order or a few pieces, we require short lead times and guarantee your order is shipped to your work location so you can keep your projects moving. For local customers, we also offer same-day pickup and delivery options.

Interested in purchasing prime or less-than-prime steel expanded metal today? Or do you have questions about our surplus expanded metal for sale? Contact one of our steel experts to help you with all your steel supply and service needs. Give us a call at 713.672.7595 today.