QUALITY STEEL SINCE 1939

Prime Steel Square Tubing

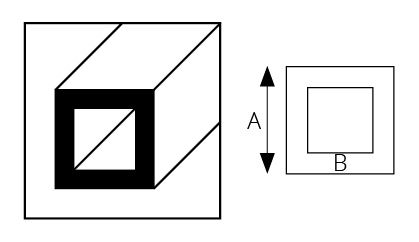

Steel tube is a common component in a wide range of fabrication and construction projects. Tubing is stronger than pipe, and carbon steel square tubing provides extreme rigidity for structural applications. Texas Iron & Metal carries an extensive selection of steel square tubing whether you need a few pieces or require enough materials for a significant project.

Texas Iron & Metal is the place to go for all your carbon steel square tubing needs. We carry different lengths and thicknesses with cross-sectional dimensions ranging from 1/2 inch on each side up to 24 inches. Projects requiring more load bearing will need larger tubes, and if you have questions about your applications, our team is happy to help. Contact us today to get help with your steel square tubing needs.

Benefits of Steel Square Tubing

Although not as strong as round tubing, galvanized steel square tubing is often preferred because of the diversity of applications. Over long distances or lengths of tubing, square tubing maintains its strength. It can resist bending over despite longer lengths of pipe and heavy pressure.

The strength rating is measured according to weight per foot. Square tubing comes in several common thicknesses, with the wall thickness increasing as the dimensions of the tube increase.

Square tubing has construction and structural uses, as well as usages in a variety of fabrication and manufacturing applications. It interlinks with other framing or tube pieces to create durable, rigid support pieces. It provides more strength than angled or channeled tubing, and it’s easily manipulated or altered for new applications through cutting or welding.

Square Tubing in stock

| image | sku | description | side | length | finish | Quantity | Add to Quote |

|---|---|---|---|---|---|---|---|

| TS11214 | 1 1/2" X 1/4" SQUARE TUBE | ||||||

| TS11211G | 1 1/2" X 11 GA SQUARE TUBE | ||||||

| TS11214G | 1 1/2" X 14 GA SQUARE TUBE | ||||||

| TS11216G | 1 1/2" X 16 GA SQUARE TUBE | ||||||

| TS112316 | 1 1/2" X 3/16" SQUARE TUBE | ||||||

| TS11411G | 1 1/4" X 11 GA SQUARE TUBE | ||||||

| TS11414G | 1 1/4" X 14 GA SQUARE TUBE | ||||||

| TS11416G | 1 1/4" X 16 GA SQUARE TUBE | ||||||

| TS111G | 1" X 11 GA SQUARE TUBE | ||||||

| TS114G | 1" X 14 GA SQUARE TUBE | ||||||

| TS116G | 1" X 16 GA SQUARE TUBE" | ||||||

| TS1216G | 1/2" X 16 GA SQUARE TUBE | ||||||

| TS1014 | 10" X 1/4" SQUARE TUBE | ||||||

| TS21214 | 2 1/2" X 1/4" SQUARE TUBE" | ||||||

| TS21212G | 2 1/2" X 12 GA SQUARE TUBE" | ||||||

| TS212316 | 2 1/2" X 3/16" SQUARE TUBE" | ||||||

| TS21211G | 2 1/2"" X 11 GA SQUARE TUBE" | ||||||

| TS214 | 2" X 1/4" SQUARE TUBE" | ||||||

| TS211G | 2" X 11 GA SQUARE TUBE" | ||||||

| TS214G | 2" X 14 GA SQUARE TUBE" | ||||||

| TS216G | 2" X 16 GA SQUARE TUBE" | ||||||

| TS2316 | 2" X 3/16" SQUARE TUBE | ||||||

| TS31214 | 3 1/2" X 1/4" SQUARE TUBE | ||||||

| TS31211G | 3 1/2" X 11 GA SQUARE TUBE | ||||||

| TS312316 | 3 1/2" X 3/16" SQUARE TUBE | ||||||

| TS314 | 3" X 1/4" SQUARE TUBE | ||||||

| TS311G | 3" X 11 GA SQUARE TUBE | ||||||

| TS314G | 3" X 14 GA SQUARE TUBE | ||||||

| TS3316 | 3" X 3/16" SQUARE TUBE" | ||||||

| TS338 | 3" X 3/8" SQUARE TUBE" | ||||||

| TS3414G | 3/4" X 14 GA SQUARE TUBE" | ||||||

| TS3416G | 3/4" X 16 GA SQUARE TUBE | ||||||

| TS412 | 4" X 1/2" SQUARE TUBE" | ||||||

| TS414 | 4" X 1/4" SQUARE TUBE" | ||||||

| TS411G | 4" X 11 GA SQUARE TUBE" | ||||||

| TS4316 | 4" X 3/16" SQUARE TUBE" | ||||||

| TS438 | 4" X 3/8" SQUARE TUBE" | ||||||

| TS612 | 6" X 1/2" SQUARE TUBE | ||||||

| TS614 | 6" X 1/4" SQUARE TUBE" | ||||||

| TS611G | 6" X 11 GA SQUARE TUBE | ||||||

| TS6316 | 6" X 3/16" SQUARE TUBE" | ||||||

| TS638 | 6" X 3/8" SQUARE TUBE" | ||||||

| TS6516 | 6" X 5/16" SQUARE TUBE" | ||||||

| TS712 | 7" X 1/2" SQUARE TUBE" | ||||||

| TS812 | 8" X 1/2" SQUARE TUBE" | ||||||

| TS9516 | 9" X 5/16" SQUARE TUBE" |